Product technical line

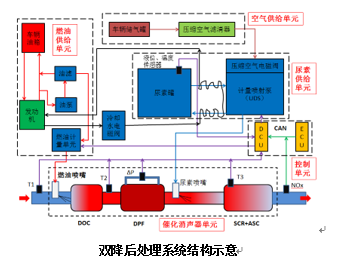

According to the requirements of the transformation and treatment of the diesel vehicle market, the product should meet the requirements of reducing both PM and NOX in the exhaust gas. Therefore, CAPT specially developed the diesel vehicle double drop post-treatment product (DOC+DPF+SCR), which better meets the market demand.

Double descending post-processing product working principle

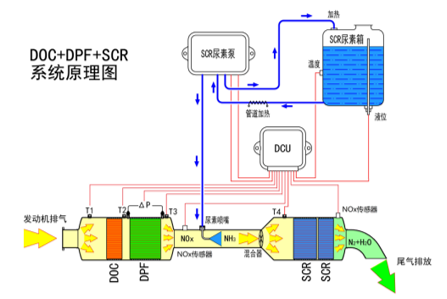

CAPT integrates diesel oxidation catalyst (DOC), diesel particulate filter (DPF), and NOx selective catalytic reducing (SCR: Selective Catalytic Reduction), successfully developed DOC+CDPF+SCR double reduction post-treatment product (a layer of precious metal catalyst is coated on the DPF carrier, namely CDPF). On the one hand, DOC in the product oxidize NO to NO2 in the appropriate temperature range, providing sufficient NO2 for the smooth passive regeneration of downstream CDPF, and also providing NO2 for the rapid reduction reaction of SCR. On the other hand, the excellent fuel ignition property of DOC is used to successfully realize the active regeneration of CDPF, improve the active regeneration efficiency of CDPF, reduce fuel consumption, and improve fuel economy.

The DOC+CDPF+SCR system integrates many modern and sophisticated technologies such as precious metal catalysts for diesel vehicles, selective catalytic reduction technology, polymer ceramic materials, high-precision sensor technology, SCR injection control technology and online monitoring and alarm technology. It is the industry leading product of road diesel engine exhaust emission control technology in China.

Products through the temperature and pressure sensors to monitor the internal working conditions of the system in real time, and uploaded to the modified vehicle monitoring platform, and through multiple temperature, nitrogen oxygen sensors and gas flow sensors or speed sensors to accurately control the NOx treatment.

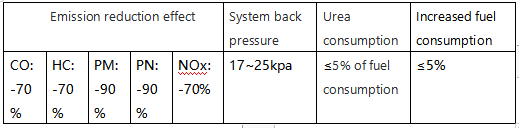

By optimizing the DOC+CDPF+SCR integrated system, the CO, HC, NOx and PM in the exhaust gas of the transformed diesel engine are significantly reduced, and the emission requirements of the regulations are met. This product after installation of fuel consumption increase not more than 5%, urea consumption does not exceed 5% of fuel consumption. Product type

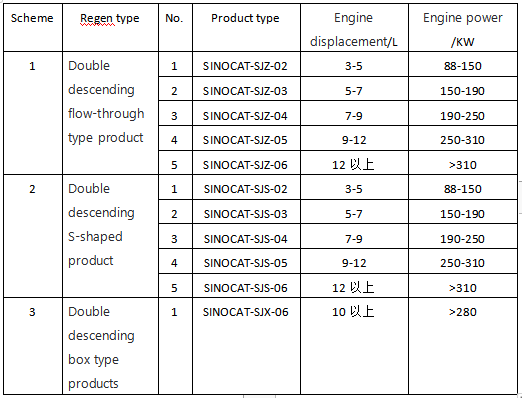

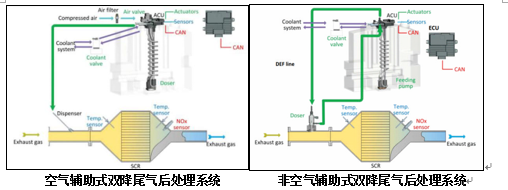

The DOC+DPF+SCR products for diesel vehicles developed by CAPT include air-assisted double drop exhaust aftertreatment system and non-air-assisted double drop exhaust aftertreatment system, and the products with different structures are designed according to the different layout of the original vehicle body. Three structures of the product

“一”-style structure

The structure is simple and practical, and can be disassembled to replace the truck with the cylinder muffler at the bottom of the original car or the vehicle with the original muffler arranged in "一" at the bottom of the vehicle.

Sshaped structure

The structure is relatively compact, the front and back two barrels can be side by side or different angles turn link, removable design, the original muffler in the side layout of the model.

Box type construction

This is the most compact structure and is ideal for replacing most square mufflers on diesel trucks. Because it can directly replace the original car muffler, so the product installation and fixation can use the original muffler fixed position and fixed way, the product installation is convenient and firm. In this way, the structure of the vehicle will not change, ensuring its safety.

Product performance parameter

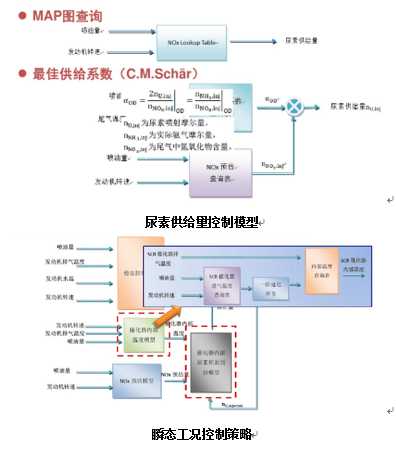

Control strategy

The control strategy of CAPT is a model-based open-loop control strategy, which uses a double nitrogen oxygen sensor and adds a feedforward control link.

Fuel suitability

CAPT products can adapt to the CN V stage vehicle diesel oil (sulfur content S≤ 10ppm). Our company's pre-sales and after-sales personnel and instructions will focus on the use of diesel oil above the CN Ⅳ standard, that is, the sulfur content is less than 50PPM. If the after-sales staff of our company doubts the user's use of non-standard diesel oil, we can negotiate with the customer to sample the diesel oil in the tank under the condition of third-party identification and send it to the third-party professional testing agency for oil identification.

The catalyst used in this system has very good sulfur resistance and can work for at least 200 hours at 350ppm fuel oil. If the truck driver accidentally adds oil that does not meet the standard, it will not have an irreversible impact on the whole system in a short time.

Experiments have been done even when the sulfur content of fuel oil reaches 3500ppm. Although the catalyst continued to work after about 20 hours of use, its performance had been significantly reduced

After switching to CN Ⅴ diesel, the catalyst can be above 350℃, after about 30 minutes, the sulfate covered on the catalyst will be removed from the surface of the catalyst (SO3&SO4), the catalyst can also successfully desulfurization regeneration, performance significantly recovered, basically can reach the initial performance state. It is proved that the modified catalyst can withstand a certain high sulfur content of diesel oil in a short time to the maximum extent.

After extracting the online monitoring data of 100 diesel vehicles, it is found that the exhaust temperature higher than 350℃ will also occur. In addition, if the DOC effect decreases, the CDPF regeneration performance also decreases, and the increase in back pressure drives the engine exhaust temperature to increase. We can also use the heating regeneration of the post-processing system during maintenance to ensure that the service life of the system is not limited by individual accidents.

产品实物图(双降S型产品实物图)

Product physical drawing (double descending S-shaped product physical drawing)

Thermal management solution

Same as: particle trap DPF

|