Product technical line

DPF (Diesel Particulate Filter) Diesel particulate trap (also known as DPF exhaust aftertreatment system), after a long time of particle trapping, will block the porous medium channel of the filter, resulting in the rise of back pressure in the exhaust system, and then affect the normal operation of the engine. Therefore, measures need to be taken to remove the soot particles filtered by DPF and restore the filtering ability of DPF, which is called regeneration. Regeneration methods are generally divided into active regeneration and passive regeneration.

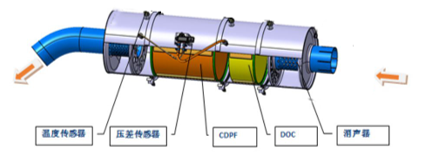

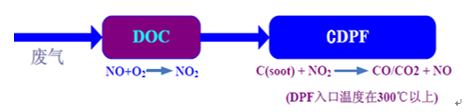

The product developed by CAPT is to reduce the emission of CO, HC and other pollutants in the exhaust gas through the oxidation reaction catalyzed by DOC. At the same time, NO in the exhaust gas is oxidized to NO2 by DOC, and the passive regeneration of PM captured by CDPF (CDPF catalyst coated on DPF carrier, namely CDPF) is realized under appropriate temperature conditions. When the condition of active regeneration is reached, the control unit controls the fuel injection device to inject oil before the DOC, and the exhaust gas temperature is greatly increased by the DOC, so that the PM in the CDPF in the back can burn and regenerate. The catalytic performance of DOC and the filtration performance of CDPF make the exhaust gas purified.

The company's products are tested according to the test standards of the Ministry of Ecological and Environmental Protection and the industry test standards (HJ451-2008). The conversion efficiency of the DOC of the catalyst in the system to HC and CO is more than 80%, the capture efficiency of DPF is more than 90%, and the regeneration efficiency of particulate matter is more than 90%.

The control unit monitors the temperature throughout the catalyst and the pressure difference before and after CDPF, and determines whether regeneration is required based on carbon loading and operating conditions. If regeneration is needed, the controller will control the active regeneration system to work. And has the remote on-line monitoring device.

(Simplified diagram of modified products)

In view of the actual situation of diesel vehicle emissions in use, taking into account the latitude and longitude of different regions and the ambient temperature in winter, CAPT provides two different transformation programs, the main difference is that the regeneration technology route is different, so as to meet the transformation requirements of various vehicles.

Product type

Fuel Adaptability

CAPT products can adapt to the national five stage vehicle diesel oil (sulfur content S≤ 10ppm)

Product Safety Requirements

(1)Product installation

Remove the original car muffler, install the product in the engine exhaust pipe, and fix it on the vehicle frame. On the premise of ensuring the installation space of the catalytic muffler, the distance from the engine should be as short as possible. If necessary, the exhaust pipe should be insulated, and the maximum distance after insulation should not exceed 2000mm.

After the installation of the product, it is guaranteed that the original safety performance of the vehicle is not changed, and it conforms to the relevant safety regulations. Starting from the safety of the system control strategy, in some special cases and occasions, the control system will force the termination of the active regeneration of the product. Including: stop the active regeneration process after parking, in special occasions (such as gas stations, flammable and explosive places, etc.)

(2)Structural security

All products and mounting brackets and other accessories are selected to meet the strength requirements of the vehicle, to prevent the product from breaking and falling off due to severe vibration during driving. The structure and size are similar to the original car muffler, which will not affect the original safety performance of the vehicle. Good thermal insulation measures to prevent fire or burns caused by high temperature.

(3)The security of the control policy

Accurate judgment of regeneration conditions to ensure timely and effective regeneration of products. Set strict thresholds for regeneration conditions, including vehicle speed, exhaust temperature, CDPF back pressure, and cumulative running time to reach the set value. After parking or in special occasions (such as gas stations, flammable and explosive places, etc.), active regeneration can be forced to terminate.

Take electricity from the standby terminal of the original car, and the system automatically shuts down after parking, which does not affect the electrical system of the vehicle. The system has its own air source, no need to take air from the original vehicle, does not affect the vehicle braking performance.

DPF exhaust aftertreatment system passive type

Principle of regeneration

Passive regeneration relies on DOC to oxidize NO in the exhaust gas into NO2, which reacts with carbon particles (soot) in DPF to achieve the function of removing carbon particles and realizing passive regeneration. At the same time, the catalyst is coated with a layer of catalyst on the DPF carrier (CDPF) was coated on the DPF carrier to reduce the temperature of carbon particles and NO2 reaction, increase the temperature range of passive regeneration, and improve the efficiency of passive regeneration.

Product Structure

The products of the two modification schemes adopt the DOC+CDPF catalytic muffler structure with direct intake or side intake. According to the different engine displacement, the product with different diameter and length is designed, and the overall structure and size are similar to the original car muffler. It can be installed after removing the original car muffler, and the installation height is equivalent to the original muffler to ensure that the passability of the vehicle is not affected.

CAPT products have high maintainability, the CDPF is designed as a removable structure. When the device accumulates more ash that cannot be burned, the CDPF section can be easily removed and the ash is blown out by using a special device. The blown air is filtered by water and will not affect the ambient air. The product has no additional vent, preventing the occurrence of emission fraud at the source.

Condition of regeneration

DOC oxidize NO from NOx in the engine exhaust to NO2, and when the temperature in the exhaust reaches 250℃-500℃, NO2 reacts with the particles in the DPF catalyst.

The principle of passive regeneration is as follows:C+NO2→CO+NOC+2NO2→CO2+2NO

The passive products require the catalytic converter to have good performance, and have certain requirements for the original emission of the vehicle, the running state of the vehicle and the quality of the fuel, and the application is limited.

Heat treatment scheme

The first scheme: The thermal management scheme of the two products developed by CAPT is to add a layer of heat insulation cover (commonly known as "thermal insulation coat") outside the main body of the product. The function of the heat insulation cover is that the sound absorption rate of the product is more than 90%, and it can prevent noise and interference, which is higher than the average requirement of NRC. With heat temperature up to 700℃, good toughness, corrosion resistance and other characteristics. It has high tensile strength and length stability, so as not to produce any dust. Very low shrinkage rate at high temperature, long service life. The high sound absorption rate can achieve the effect of noise reduction, and the high heat insulation resistance enables the fuel to fully react in the high temperature environment in the exhaust pipe, so as to achieve low emissions.

Technical requirements for heat shields:

The heat shield is an inorganic fiber composite product. Its physical and chemical properties are as follows: room temperature thermal conductivity ≤ 0.04W/mK, tensile strength ≥ 0.72MPa, non-combustible grade A, safe use temperature is not less than 600℃. The heat shield should be reliable, geometrically invariant, not broken, not peeled off, not clumped, not falling, not producing dust, etc. Heat shield should not burn, non-toxic, do not produce toxic substances and gases. When the heat shield is installed, the sleeve is closed on the outer surface of the pipe fittings, and the fit is required to be tight. Pass the connecting pin of the heat shield through the round hole of the cotter pin on both sides of the lap joint in turn, and tighten and fix.

The second scheme:when the temperature of DOC outlet is greater than the set value, stop the injection; Or when the temperature of the CDPF outlet is greater than the set value, stop the injection. Both of these methods can achieve a thermal management effect.

Solutions to cope with low temperature environments and unattainable regenerative conditions.

The passive product of DPF exhaust gas post-treatment system increases the probability of passive regeneration by adding catalyst coating and adding a layer of heat shield. In the case of low temperature environment and unable to achieve regeneration conditions, it is recommended that the driver increase the load or run at a high speed for 15~30min, or consider disassembly or regular manual maintenance of CDPF and manual removal of soot, such as high-pressure air flow blowing back and other emergency measures.

⑥Product physical drawing

|