|

Product Technical Route

After a long time of particle trapping, the DPF will block the porous medium channel of the filter, resulting in increased back pressure in the exhaust system, which will affect the normal operation of the engine. Therefore, measures should be taken to remove the soot particles filtered by DPF and restore the filtration capacity of DPF. This method is called regeneration. Regeneration methods are generally divided into active regeneration and passive regeneration.

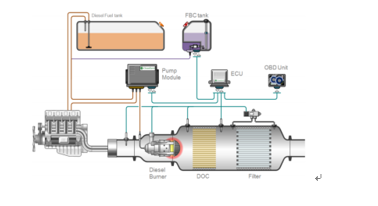

The product developed by CAPT is to reduce the emission of CO, HC and other pollutants in the exhaust through the catalytic oxidation reaction of DOC, and at the same time, DOC oxidize NO in the exhaust into NO2. Under the appropriate temperature conditions, CDPF(catalytic converter coated with a layer of catalyst on the DPF carrier, namely CDPF) can capture the passive regeneration of PM. When the condition of active regeneration is reached, the control unit controls the injection device to inject oil in front of DOC, and uses DOC to greatly increase the exhaust temperature, so that PM in the CDPF behind can be used for combustion regeneration. The catalytic performance of DOC and the filtration performance of CDPF make the tail gas purified.

The company's products were tested according to the testing standard of the Ministry of Ecology and Environmental Protection and the industrial testing standard (HJ451-2008). The DOC of the catalyst in the system has a conversion efficiency of more than 80% for HC and CO, and the DPF has a capture efficiency of more than 90% for particulate matter and a regeneration efficiency of more than 90% for particulate matter.

The control unit monitors the temperature of the catalyst and the pressure difference before and after the CDPF, and determines whether regeneration is necessary based on the carbon load and working condition. If regeneration is required, the controller will control the active regeneration system. And with remote online monitoring device.

(The product schematic)

According to the actual situation of diesel vehicle emissions in use, CAPT provides two different transformation schemes considering the longitude and latitude of different regions and the ambient temperature in winter. The main difference is that the regeneration technology routes are different to meet the transformation requirements of different vehicles.

Product Type

Adaptability of fuel

CAPT products can adapt to the CN Ⅴ stage vehicle diesel (sulfur content S≤ 10ppm)

Product Safety Requirements

(1)Product installation

Remove the original car muffler, install the product on the engine exhaust pipe, and fix it on the vehicle frame. On the premise of ensuring the installation space of the catalytic muffler, the distance from the engine should be as short as possible. If necessary, the exhaust pipe should be insulated, and the maximum distance after insulation should not exceed 2000mm.

After the installation of the product, the original safety performance of the vehicle is guaranteed and the relevant safety regulations are met. From the safety of the system control strategy, the control system will forcibly terminate the active regeneration of the product under some special circumstances and occasions. Including: stop the active regeneration process after parking, in special occasions (such as gas stations, inflammable and explosive places, etc.)

(2)Structural security

All products and mounting brackets and other accessories are selected to meet the strength requirements of the vehicle, to prevent the product from breaking and falling off due to severe vibration during driving. The structure and size are similar to the original car muffler, which will not affect the original safety performance of the vehicle. Good thermal insulation measures to prevent fire or burns caused by high temperature.

(3)The security of the control policy

Accurate judgment of regeneration conditions to ensure timely and effective regeneration of products. Set strict thresholds for regeneration conditions, including vehicle speed, exhaust temperature, CDPF back pressure, and cumulative running time to reach the set value. After parking or in special occasions (such as gas stations, flammable and explosive places, etc.), active regeneration can be forced to terminate.

Take electricity from the standby terminal of the original car, and the system automatically shuts down after parking, which does not affect the electrical system of the vehicle. The system has its own air source, no need to take air from the original vehicle, does not affect the vehicle braking performance.

DPFDPF exhaust gas aftertreatment system burner model

Principle of regeneration

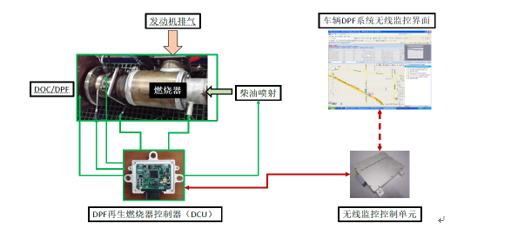

The burner type of DPF exhaust gas post-treatment system adopts the active + passive combined regeneration burner scheme. The passive regeneration scheme is consistent with the passive type of DPF exhaust gas post-treatment system, so it will not be repeated here. The burner ignition regeneration system uses working time (such as continuous working for 8 hours) + pressure difference to detect the soot load in CDPF and trigger active regeneration. The controller burns the injected fuel in the burner by controlling the amount of fuel injection, the amount of air intake and the ignition plug, and the exhaust gas temperature is rapidly increased, so that the temperature at the CDPF inlet reaches more than 500℃. Active regeneration of CDPF was achieved.

The system selects suitable operating conditions for regeneration, adopts closed-loop control, monitors the temperature at both ends of DOC and controls the amount of fuel injection and air to ensure the temperature needed for regeneration, and avoids the loss of regeneration control and damage to CDPF carrier.

Product Structure

Same as: ①DPF exhaust gas post-treatment system passive type

Reproducing Conditions

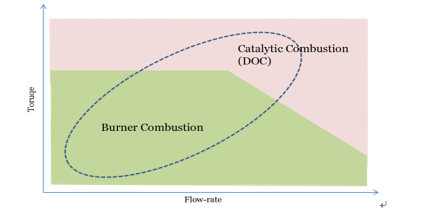

It can be seen from the above figure that the regeneration conditions of the system products are as follows: the regeneration of the burner can be achieved within the temperature of 300℃ and below the moderate exhaust flow.

Active regeneration device structure

Regenerative control strategy

The burner ignition regeneration system uses working time (such as continuous working for 8 hours) + pressure difference to detect the soot load in CDPF and trigger active regeneration. The controller burns the injected fuel in the burner by controlling the amount of fuel injection, the amount of air intake and the ignition plug, and the exhaust gas temperature is rapidly increased, so that the temperature at the CDPF inlet reaches more than 500℃. Active regeneration of CDPF was achieved.

Thermal management solutions

Same as: DPF exhaust gas aftertreatment system passive type

Product Photo Show

|